SDI Services & Capabilities

SDI handles every step of wire harness assembly under one roof, using streamlined processes to ensure top-notch quality.

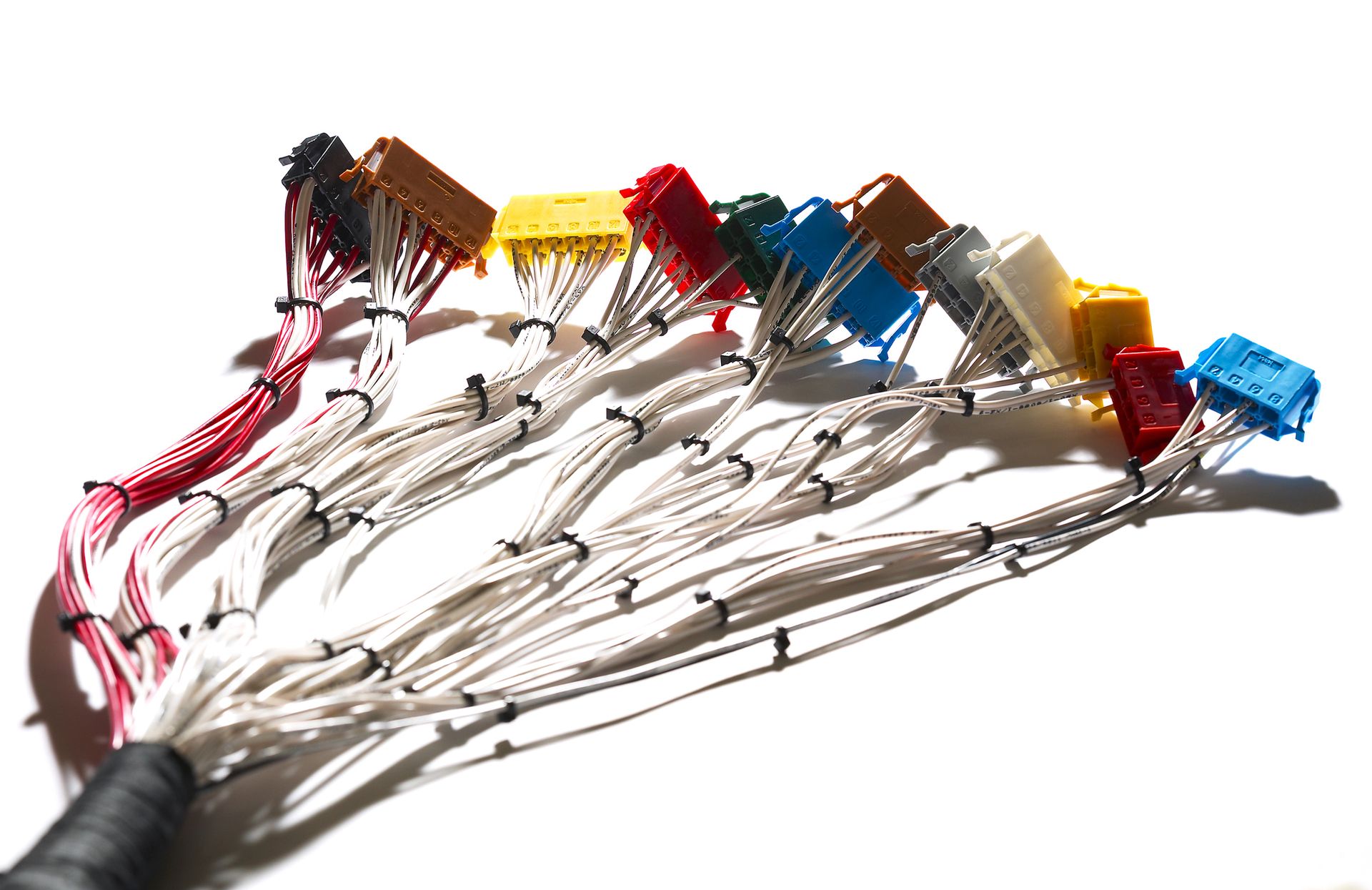

Semi-Automatic Crimping

Our semi-automatic crimping equipment handles everything from low-volume prototypes to high-volume production.

Automated Cut & Crimp Centers

Our automated cut & crimp centers reduce labor costs, improve repeatability, and ensure consistent quality. Fast changeovers and lights-out operation shorten lead-times.

Design & Prototyping

Partner with SDI to design and prototype your new harness. A well-executed design streamlines assembly, boosts durability, and optimizes performance.

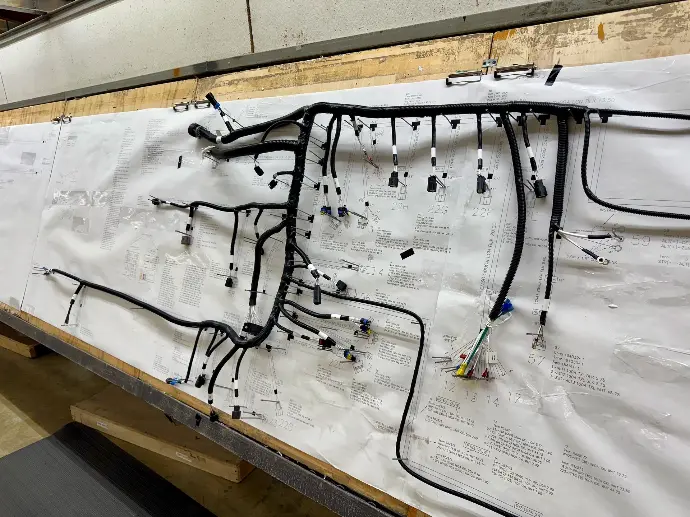

Assembly Boards

Our board room is spacious enough for harnesses of all sizes. Rigorous revision control and detailed drawings support consistent production.

Braiding

With 14 braiding machines in-house, SDI has the capacity to increase throughput and meet the tightest delivery schedules.

Testing

Every harness SDI builds undergoes dedicated testing with tailored equipment, so we know it meets specifications before it ships.